Our gene

therapy platform

Realizing the Promise of Gene Therapy

At Ultragenyx, we have developed one of the largest advanced clinical gene therapy portfolios in the industry.

Ultragenyx has nearly a decade of experience with gene therapy, having studied AAV-based investigational therapies across multiple clinical studies, with more than 100 patients dosed and many years of follow-up. Today, as a complement to our diverse pipeline, we have multiple clinical-stage gene therapy programs and anticipate two FDA approvals in the coming calendar year.

As scientific progress has advanced, so has our understanding that the complexity of gene therapy manufacturing can be a barrier to the development of such therapies. Ultragenyx realized that the best way to bring gene therapies to families in need would be to establish our own end-to-end gene therapy R&D and good-manufacturing practices (GMP compliant) manufacturing and testing capabilities at scale.

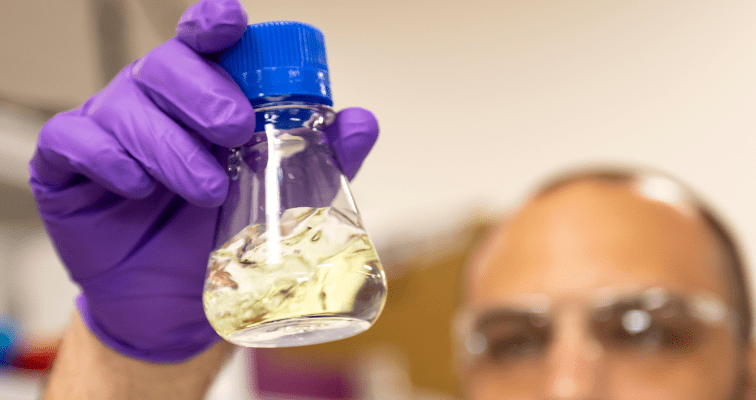

Taking Manufacturing into Our Own Hands

In 2023, we opened our state-of-the-art 112,500-square-foot Gene Therapy Manufacturing Facility (GTMF) in Bedford, Massachusetts, providing us with end-to-end gene therapy R&D and manufacturing capabilities. This fit-for-purpose GMP drug substance and drug product facility can enable future process innovation and multi-modal process configurations, supporting our goal of delivering new treatments to patients as quickly as possible.

In addition, in the Greater Boston area, we operate a 500L scale Pilot Plant and advanced GMP QC laboratories. These facilities, located near the GTMF, support our fully integrated end-to-end gene therapy R&D capabilities and position us at the forefront of industry developments in gene therapy.

While we will continue using a hybrid manufacturing strategy of contract manufacturing organizations and in-house capabilities, integration of our gene therapy research, development, and manufacturing will streamline and accelerate the process and ensure we meet the urgent needs of patients facing rare diseases.

End-to-End Gene Therapy R&D and Manufacturing Capabilities

We employ a variety of platforms and technologies across our gene therapy clinical programs, coupled with our HEK manufacturing platform that supports our most advanced clinical-stage gene therapy programs. HEK enables efficient and scalable production of AAV to reliably deliver products of the highest purity and potency, to help meet the rising demands of today’s gene therapy landscape. This capability is invaluable as we prepare to launch DTX401, an investigational gene therapy for the treatment of GSDIa, which is manufactured entirely in house using our HEK-293 cell system.

Today, we are manufacturing at the 500-liter and 2,000-liter scale, fill our drug product using state of the art isolator technology and test our products using advanced technologies. Ultimately, this brings us closer to our goal of developing therapies faster and more reliably for the people who need them.

Strengthening Our U.S. Manufacturing Footprint

Photo: Drug substance manufacturing technicians working on single use bioreactors in the cell expansion suite.

Discover more about Ultragenyx:

Pipeline

See the progress we have made with our diverse portfolio of investigational therapies.

View our pipeline